Fleet Size

Need

Vessel Type

Migration

About Us

Create

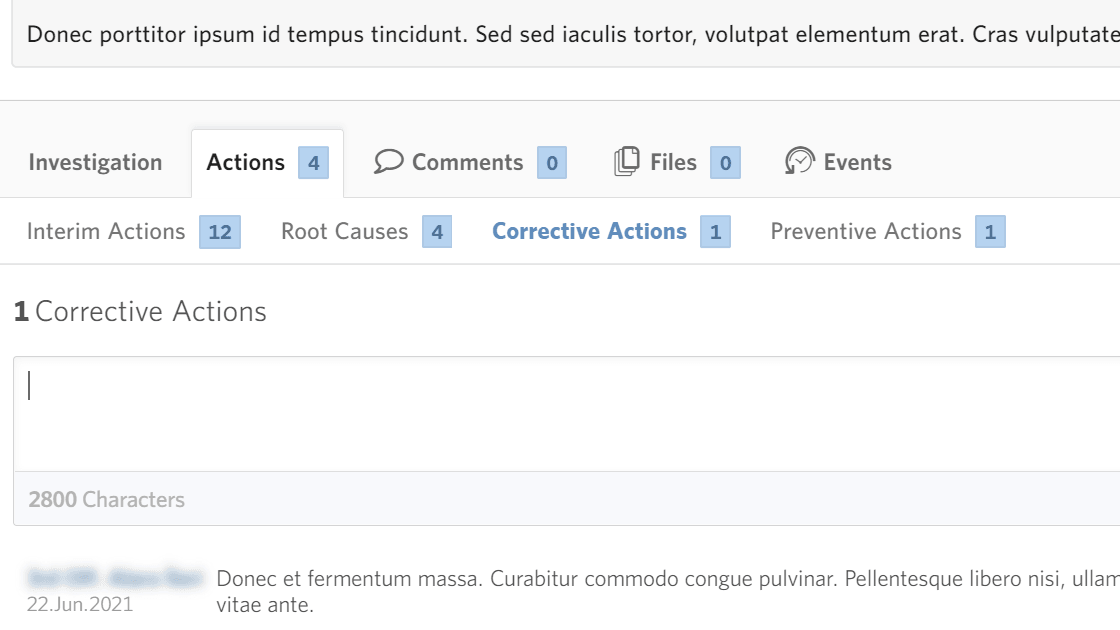

All actions taken about issues (Interim, Root Causes, Corrective Actions, Preventative actions) are kept in an easily filled format to be analyzed.

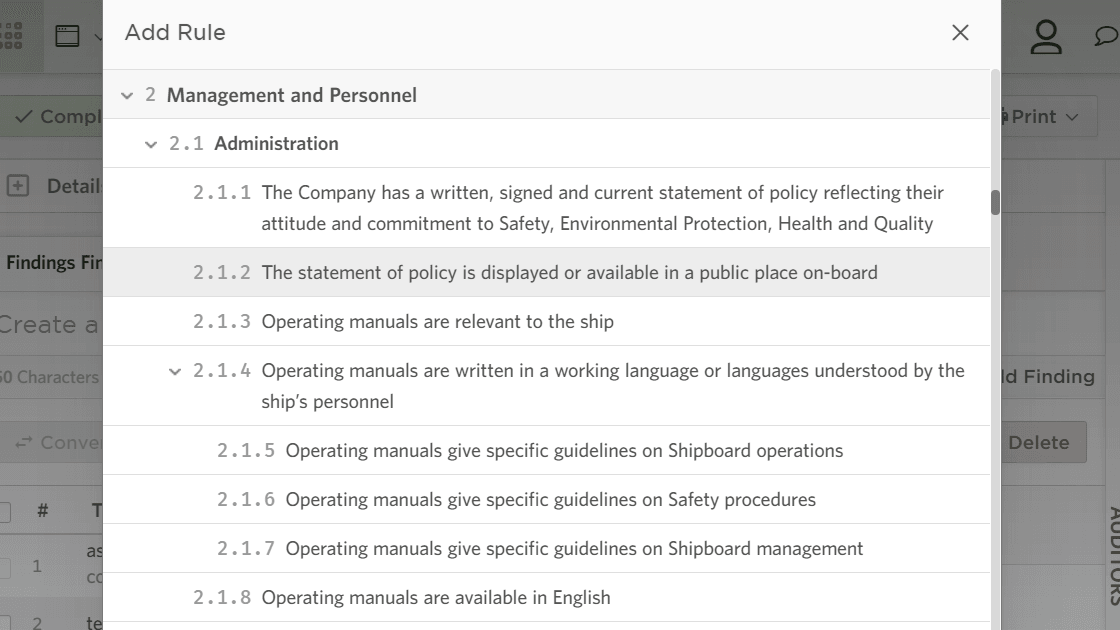

You can create your own root cause systems and assign them to be used in any issue type.

Filing an issue correctly requires domain knowledge about various rules and regulations. Reporting an inquiry, on the other hand, is very easy for crew members. You can opt in to let the crew fill Enquiries and later convert them to various issue types.

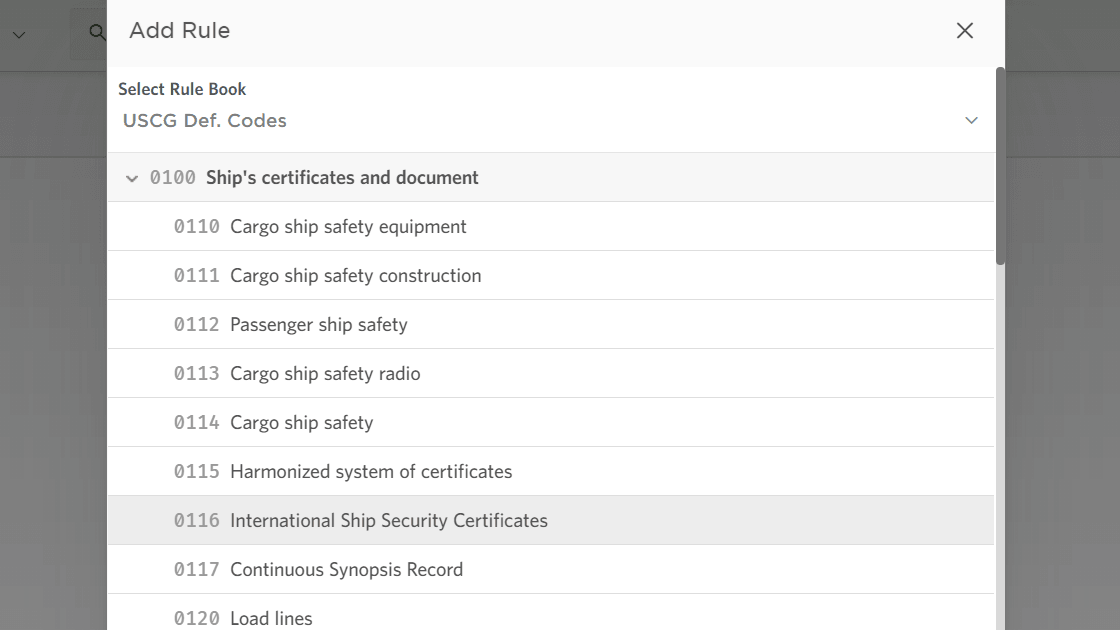

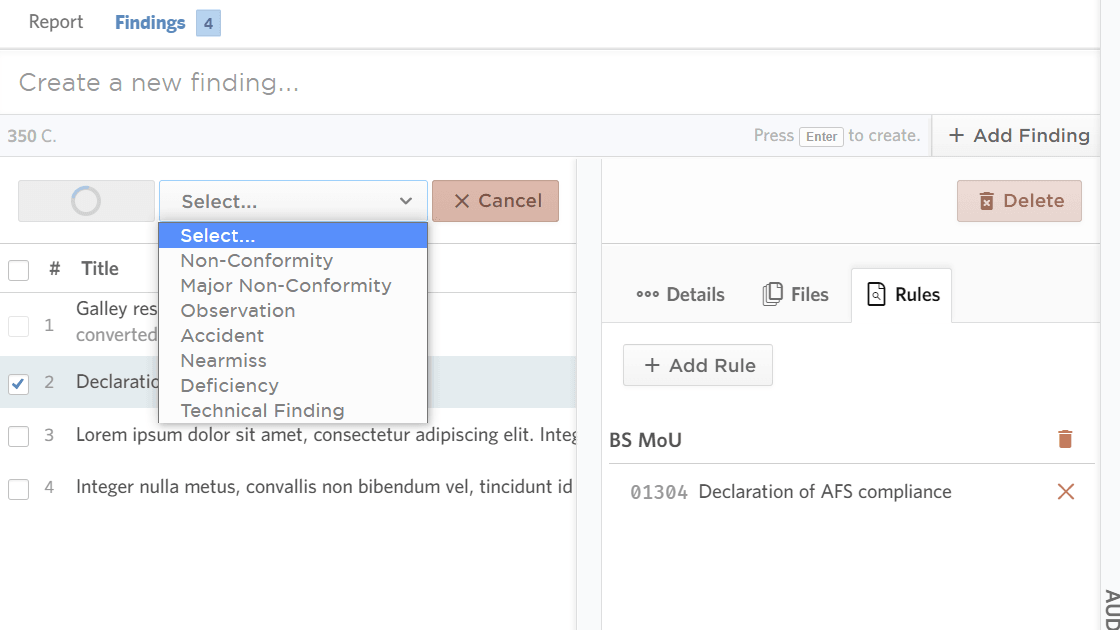

Navatom keeps an up-to-date list of rules and regulations, which is used to help select fields in various forms and reports.

Due dates are visible on the calendar, and all other views that show time tracking.

You can report issues as closed, fixed, or duplicate, the resolution helps you to sort through open issues faster.

You can define multiple root causes, and rule systems that your users can select while reporting issues. Analytics work together with user-generated rule systems, to show recurrence and volume of specific causes and rules.

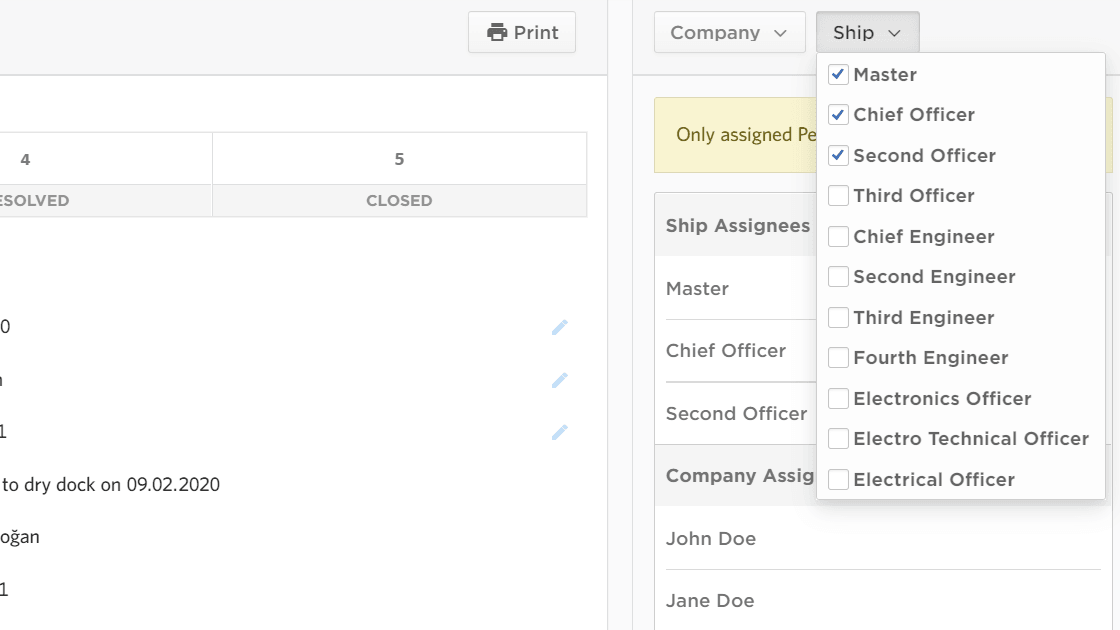

Assign

With dynamic assignments, you can control who can view or edit a report on a per report basis. This also allows tracking responsibilities across assigned items.

The newsfeed also has a personalization feature that allows users to view feeds on items assigned to them specifically.

Report

The deficiencies module has a direct link to your equipment, you can create deficiencies directly related to your equipment, and run intelligent filters and analytics on a per equipment basis.

Internal and external inspections frequently result in observations that you need to follow up on. These observations can be transformed into issues to create detailed reports of each account.

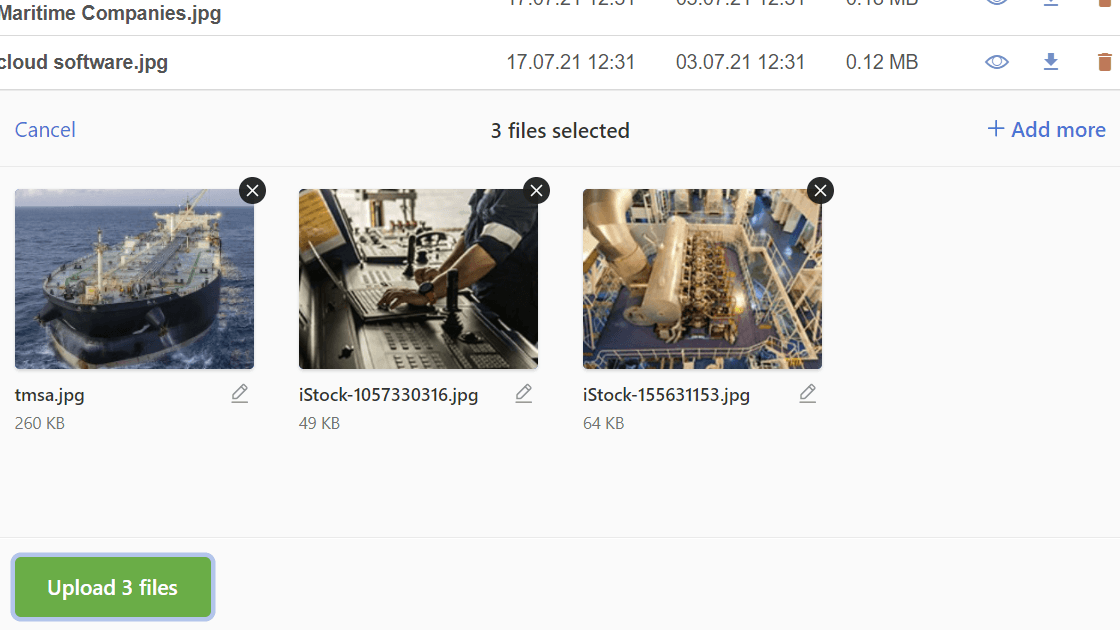

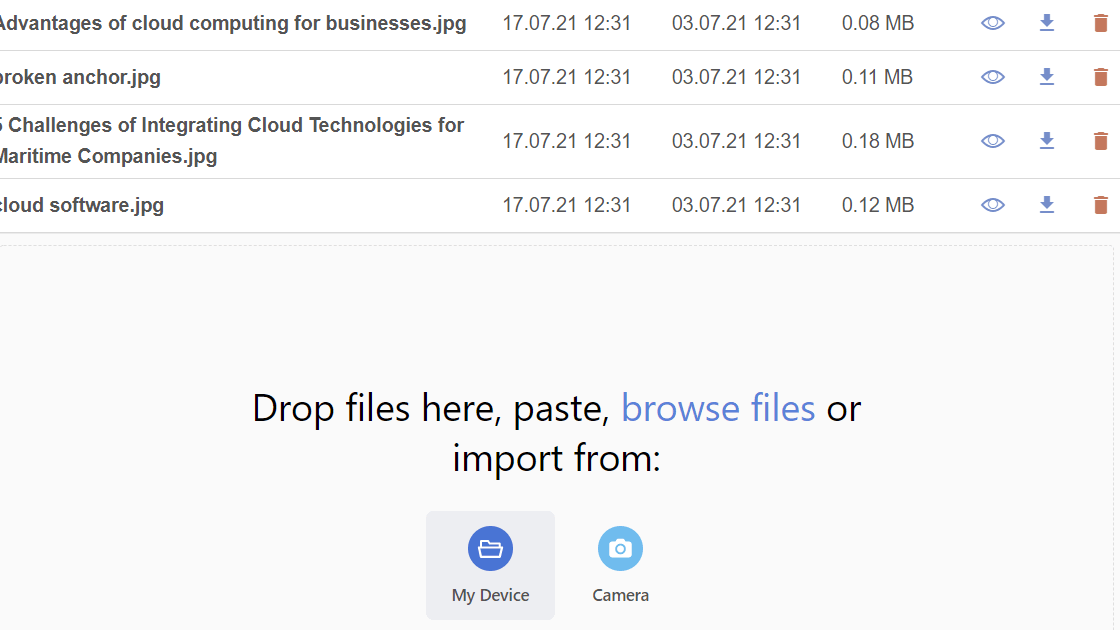

Attach all types of files to a report. The files can be previewed if the file type allows it, or downloaded. Navatom allows file attachments everywhere that's necessary.

Interact

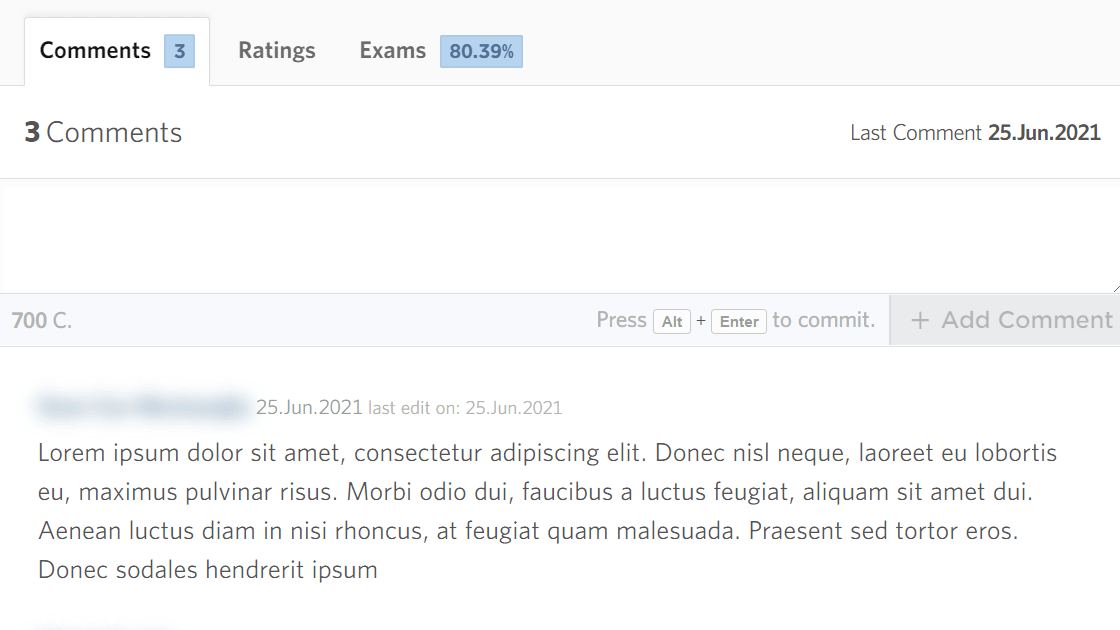

An easy-to-use commenting system that allows managers and crew converse on a specific task or procedure.

Follow Up

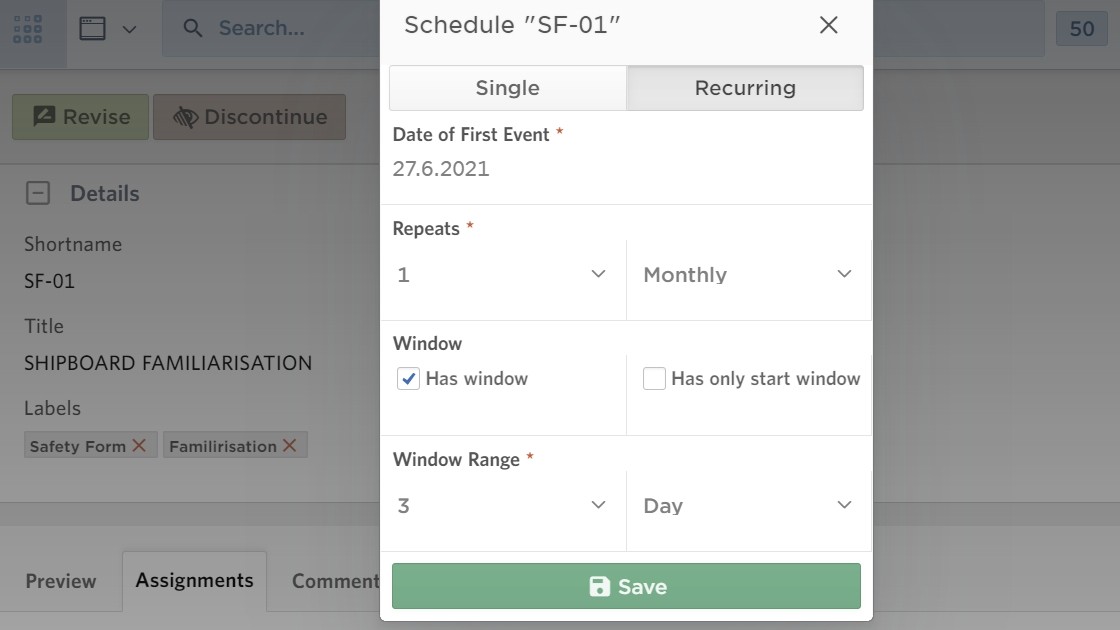

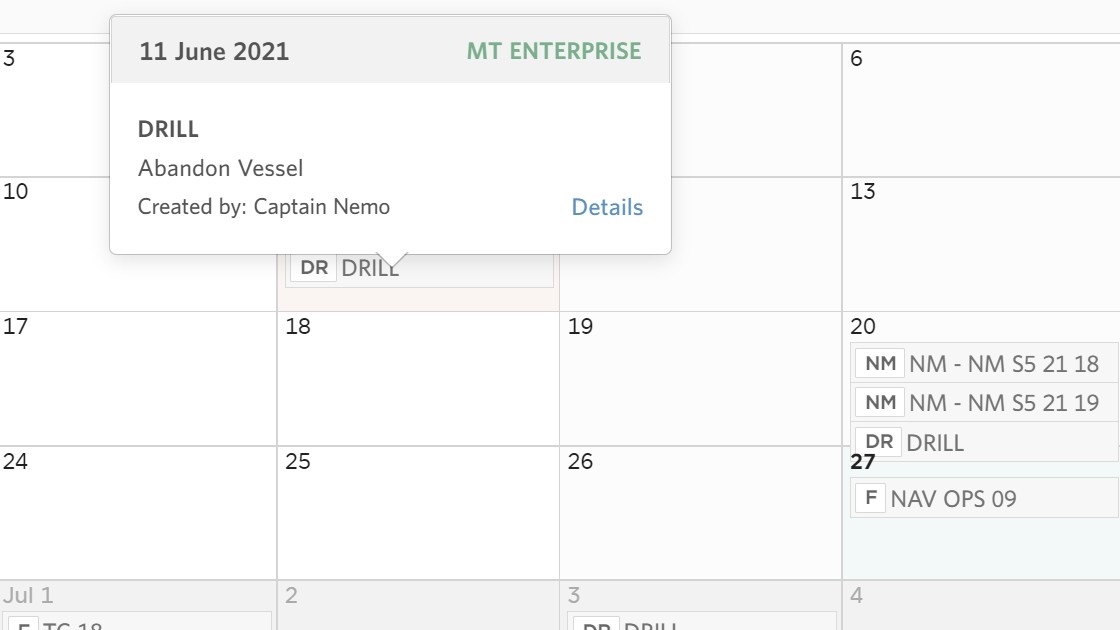

The calendar gives a monthly/yearly view of all of the periodical tasks in Navatom, you can also create and assign events here. Scheduled events are shown and can be started from the calendar view.

All issues can be postponed to a scheduled drydock. When the drydock has started a list of postponed issues will be available as tasks.

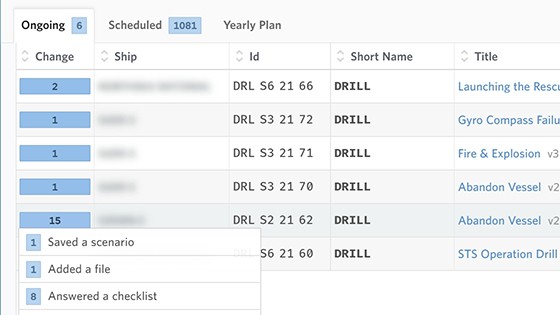

Labels in a table view show the details of what has changed since you've last viewed this item. This list of changes uses the newsfeed to populate which items have been changed since your last view.

Follow the stages of an issue or report until completion.

Log

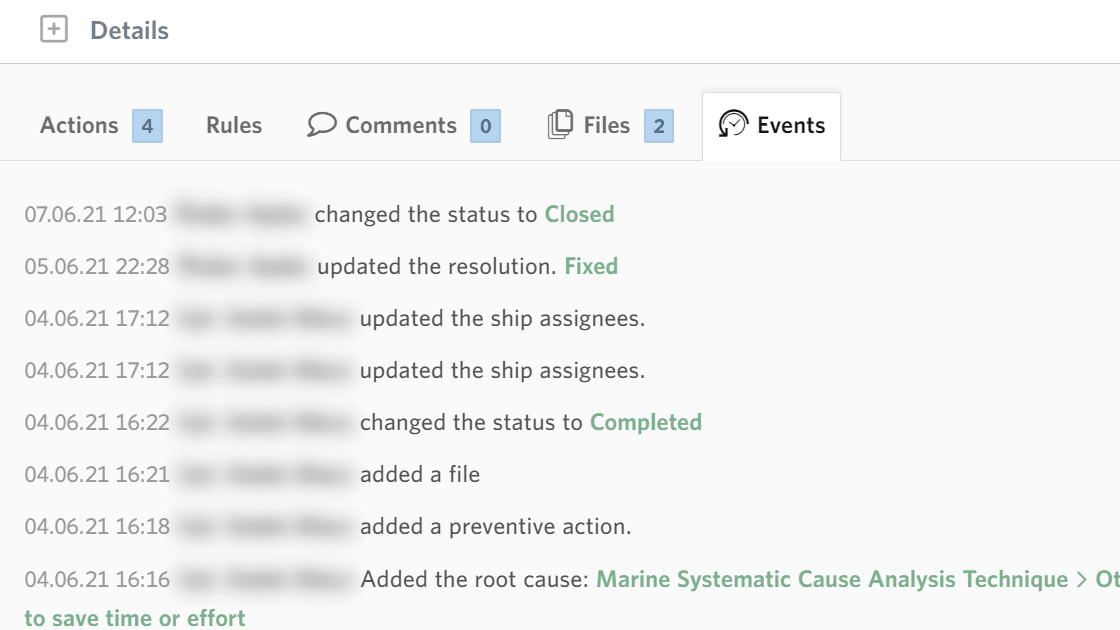

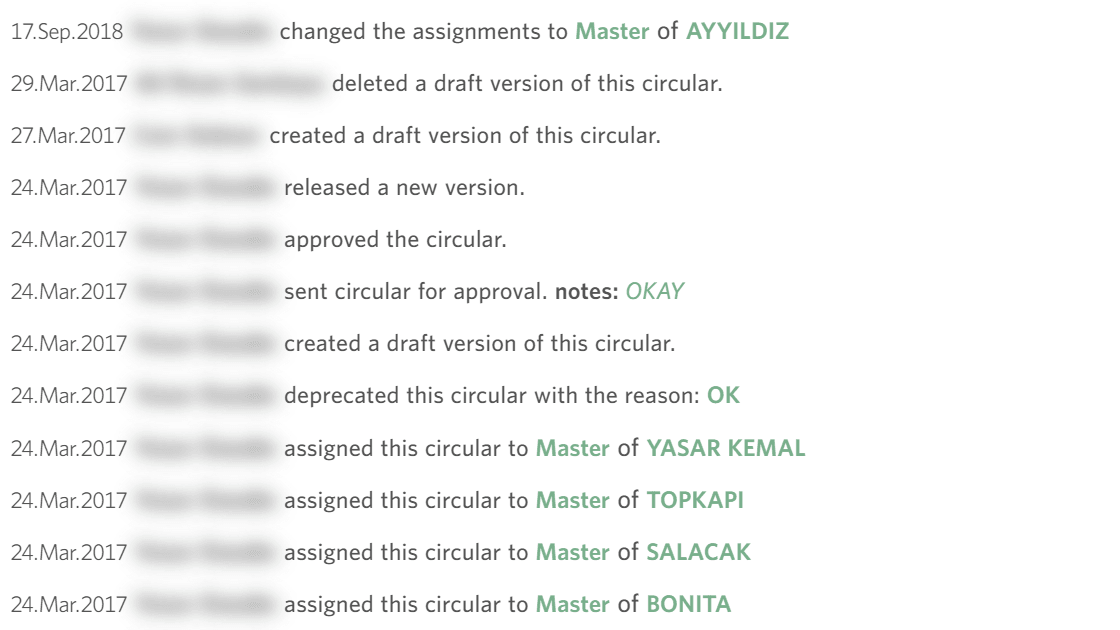

Navatom keeps detailed logs of all actions taken by everyone in your organization.

Manage

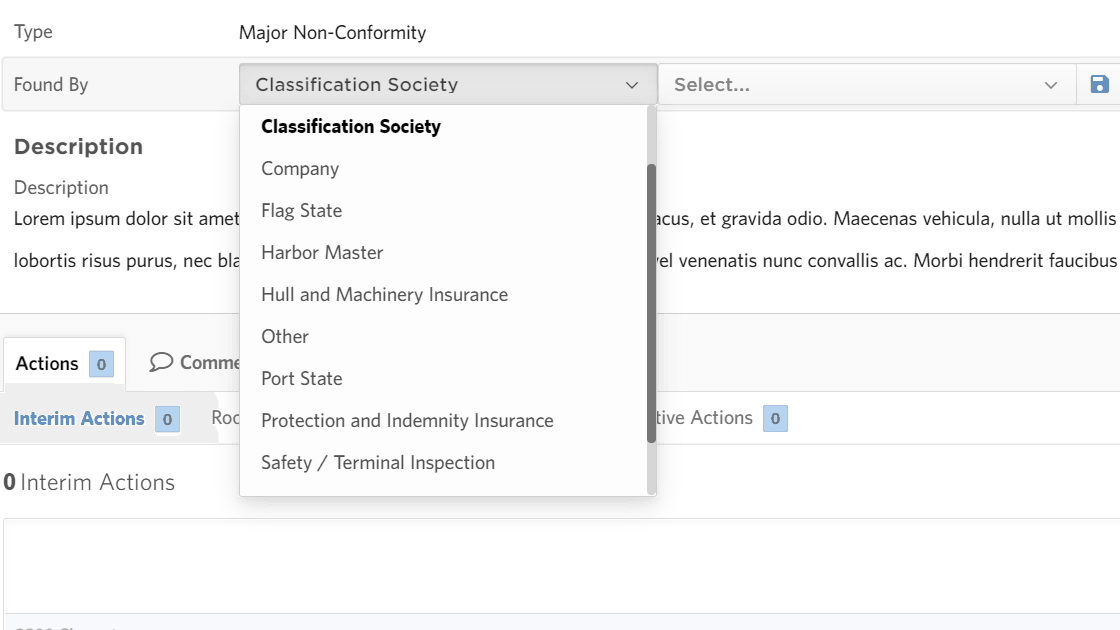

Select finding or inspecting authority from a predefined list kept within the system. Navatom keeps a full list of all third-party inspection including but not limited to:

Flag States

Classification Societies

Port States

Major Oil Companies