Fleet Size

Need

Vessel Type

Migration

About Us

Create

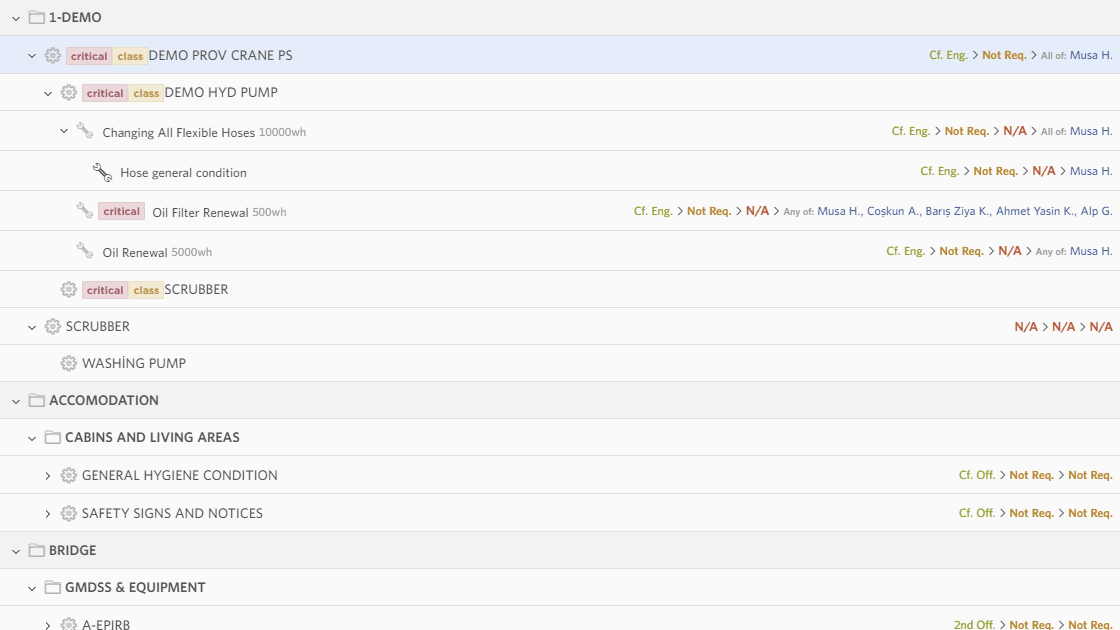

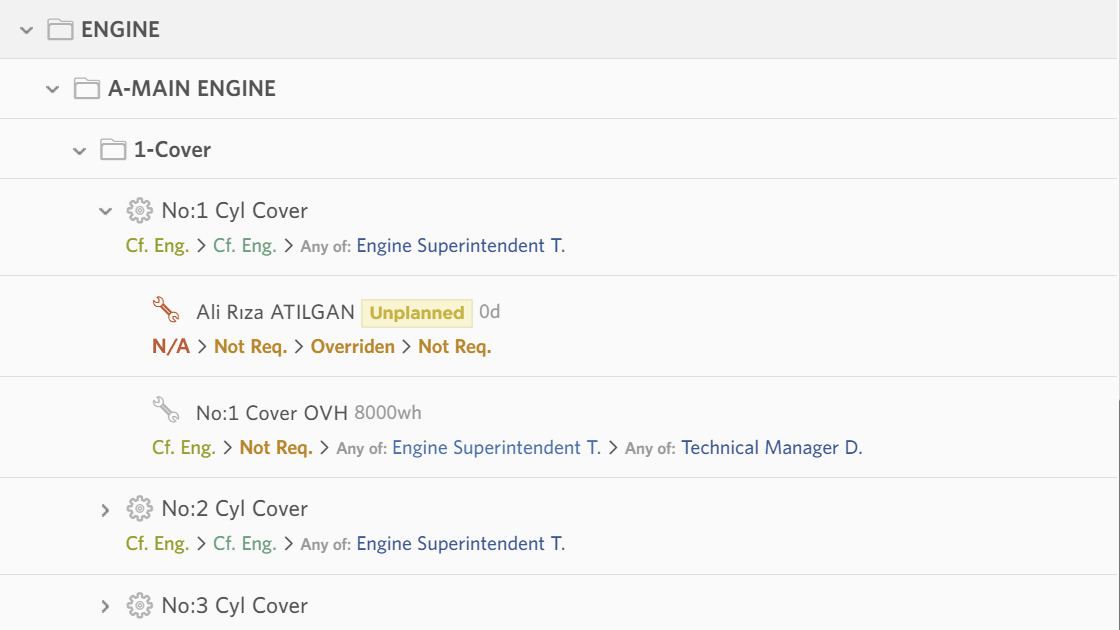

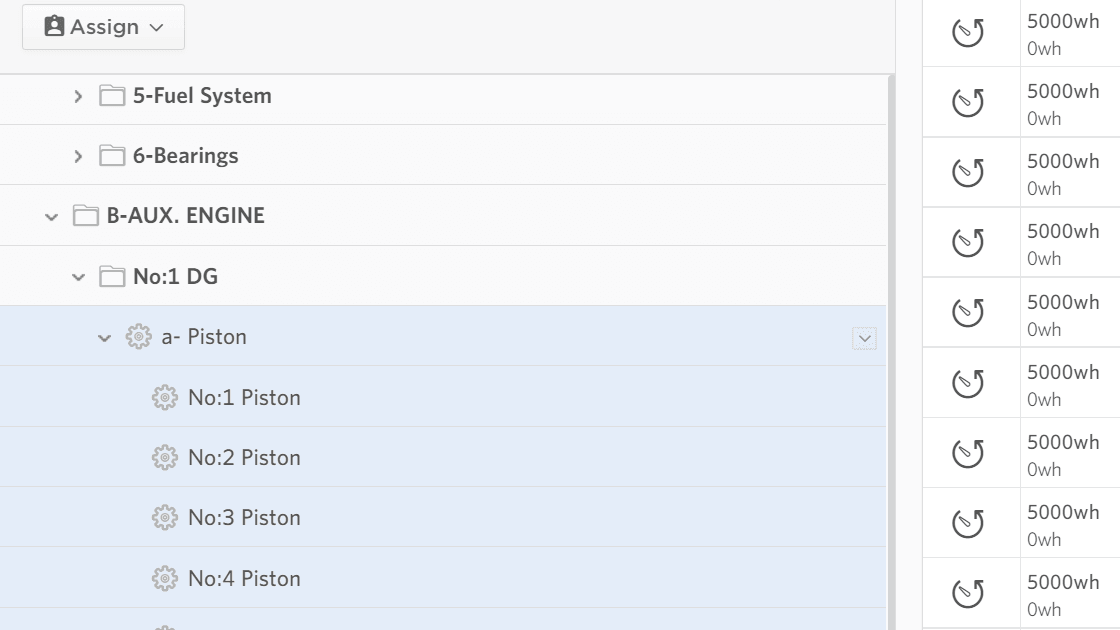

Equipments can be infinitely nested to deliver realistic equipment hierarchies (i.e. Main Engine > Cylinders > Cylinder No.1 > Head)

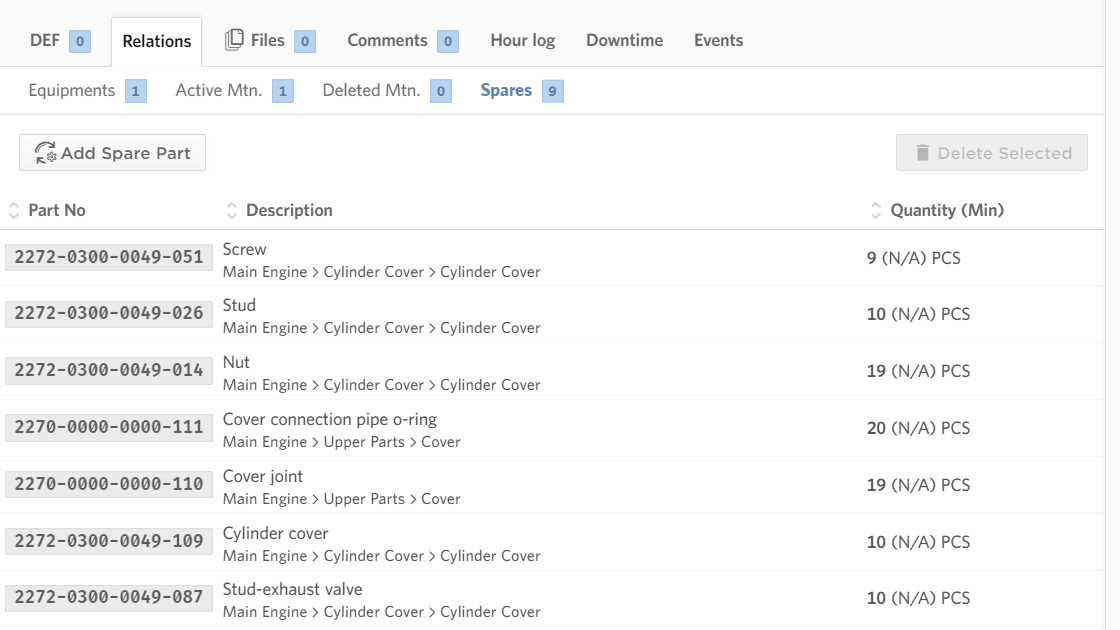

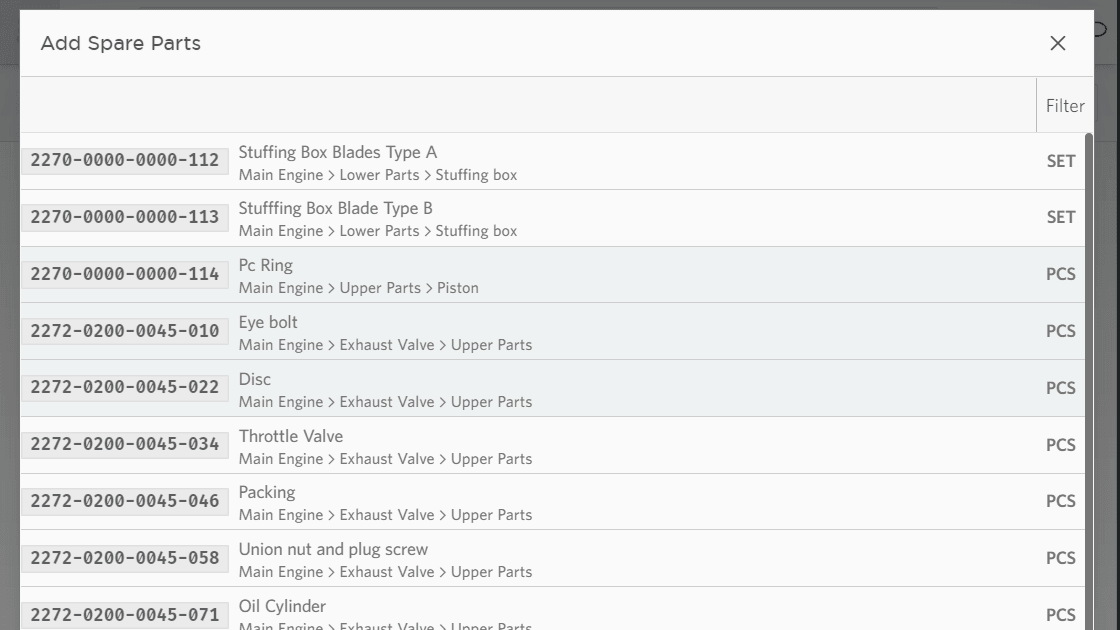

Spare parts can be directly defined on a per equipment (or sub-equipment) basis. You can easily add spare parts to your defined equipment, these lists are then shown when the crew are doing maintenances and reporting spare part usage

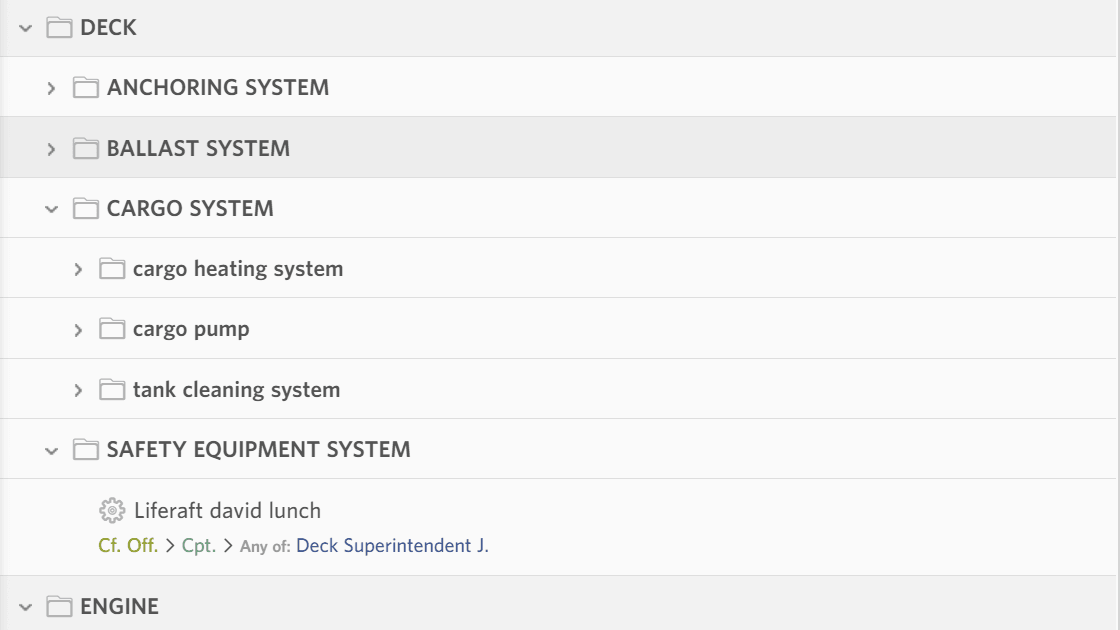

To clarify, sort and filter equipment Navatom delivers infinitely nested category system, categories contain equipment. With a nested category system it's easier to sort equipment based on either location or functionality.

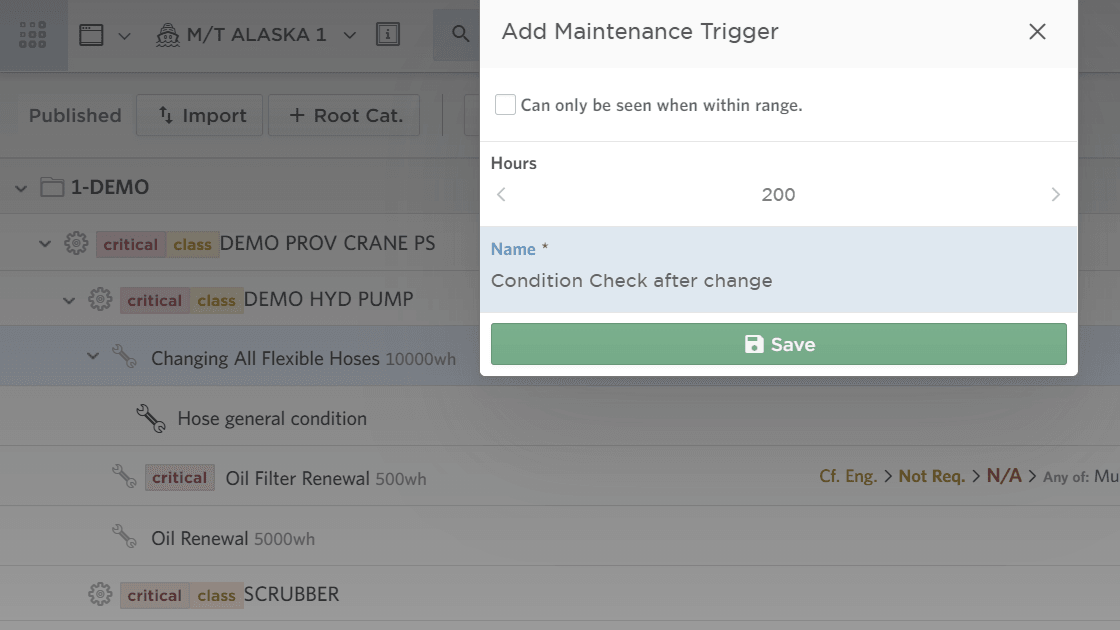

As listed in some equipment technical manuals, triggered maintenance is started based on their parent maintenance (i.e., run a visual check 200wh after the overhaul).

In legacy software or paper-based PMS, some maintenances are skipped or given arbitrary planning. This feature allows a deeper understanding and realism for the PMS.

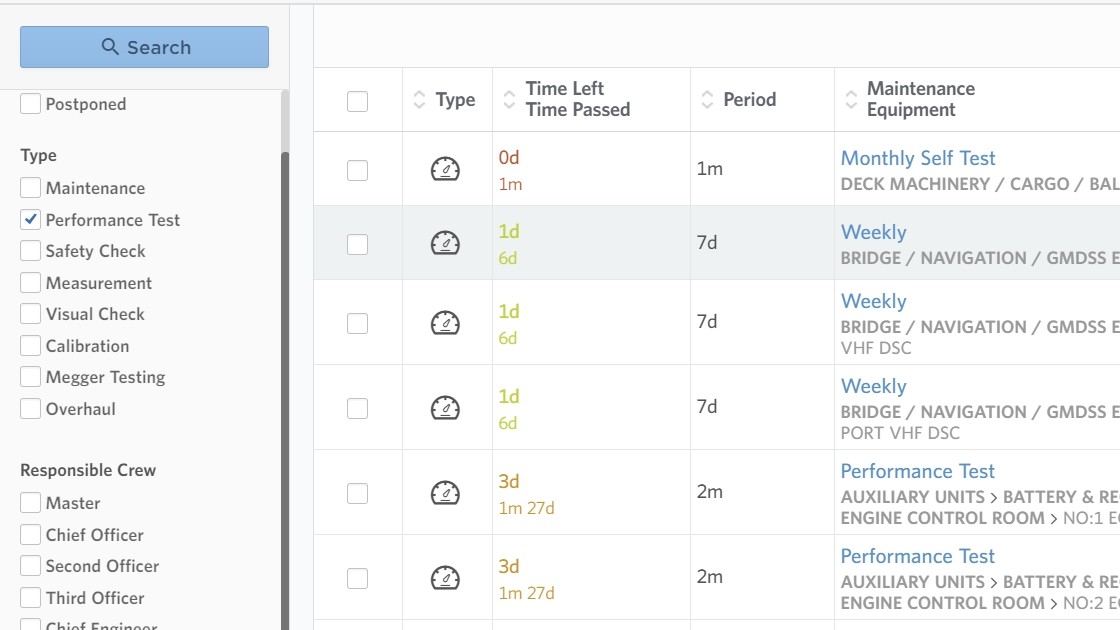

The PMS tasks in Navatom are separated into types, these are, Maintenance, Safety Check, Performance Test, Visual Check, Meger Test, and Overhaul.

You can export whole categories to other ships, duplicate equipment maintenances or categories (copying all definitions within that tree).

Allowing nested equipment brings a cumbersome task with it, you want to add cylinders separately within the main equipment, but your vessel has 8 of them, duplication allows you to create one duplicate it with the click of a button, and change hours if necessary. You can copy whole categories of equipment within a ship, or to other ships. If you have sister ships, you can actually duplicate the whole PMS structure (with its instructions, spare part definitions, etc.) to another one of your ships.

Reports are entered through a WYSIWYG (What you see is what you get) editor that allows inserting rich text, images and links to a report.

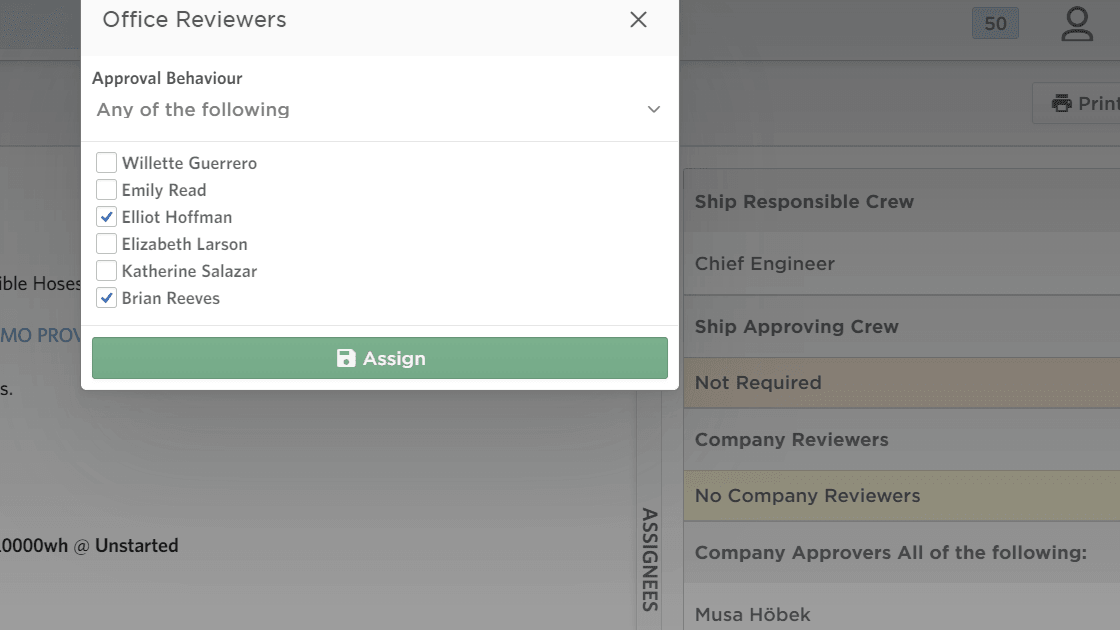

Assign

Planned maintenances can be assigned in four levels, Ship responsible, ship approver, company reviewer, company approver. Ship responsible is the only required step.

Risk assessments can be added to maintenance definitions, these risk assessments are then presented to your crew members while they are on the maintenance details report.

Assign a task to be reviewed then approved by people at your company. Reviewers or approvers can be chained by using a conditional (and/or) system, whereby only one reviewer/approver within a list of people is enough, or you want all of them to progress to complete a task.

Report

The deficiencies module has a direct link to your equipment, you can create deficiencies directly related to your equipment, and run intelligent filters and analytics on a per equipment basis.

A form generated within Forms can be assigned to a task. When the crew is reporting this task they have to fill the related form to complete the task. If no form is attached a rich text report area will show in its place.

A crew member can report usage of spare-parts during a maintenance.

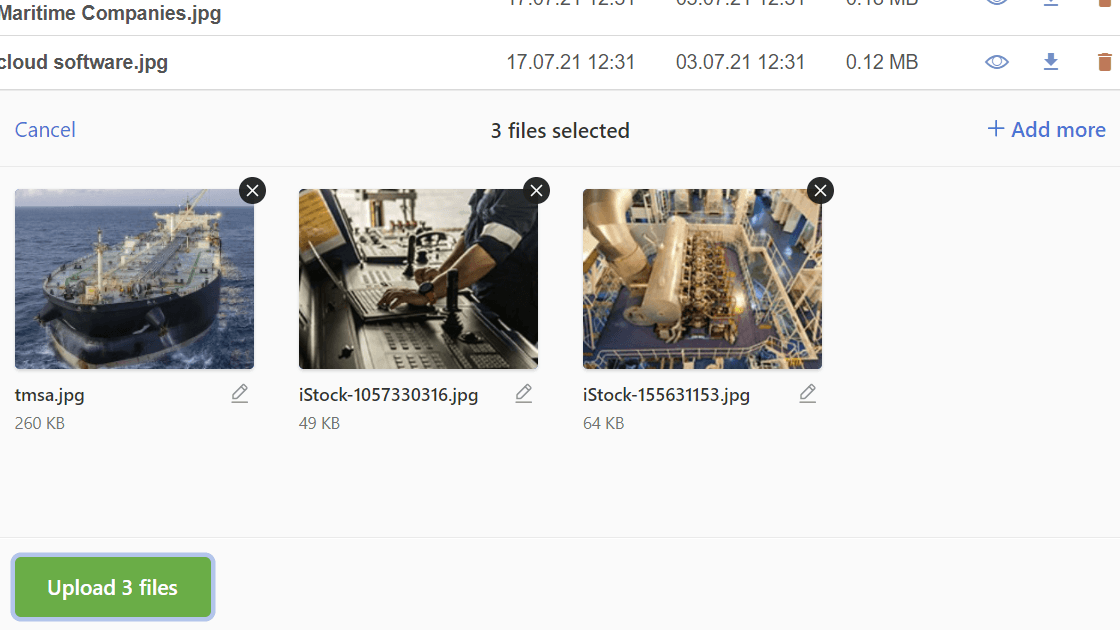

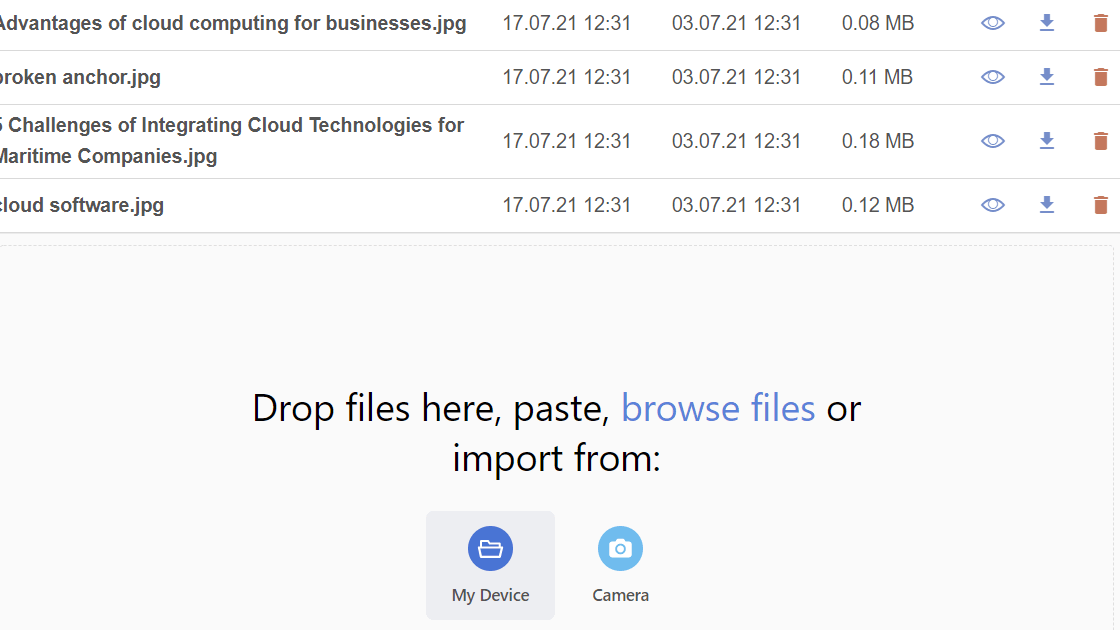

Attach all types of files to a report. The files can be previewed if the file type allows it, or downloaded. Navatom allows file attachments everywhere that's necessary.

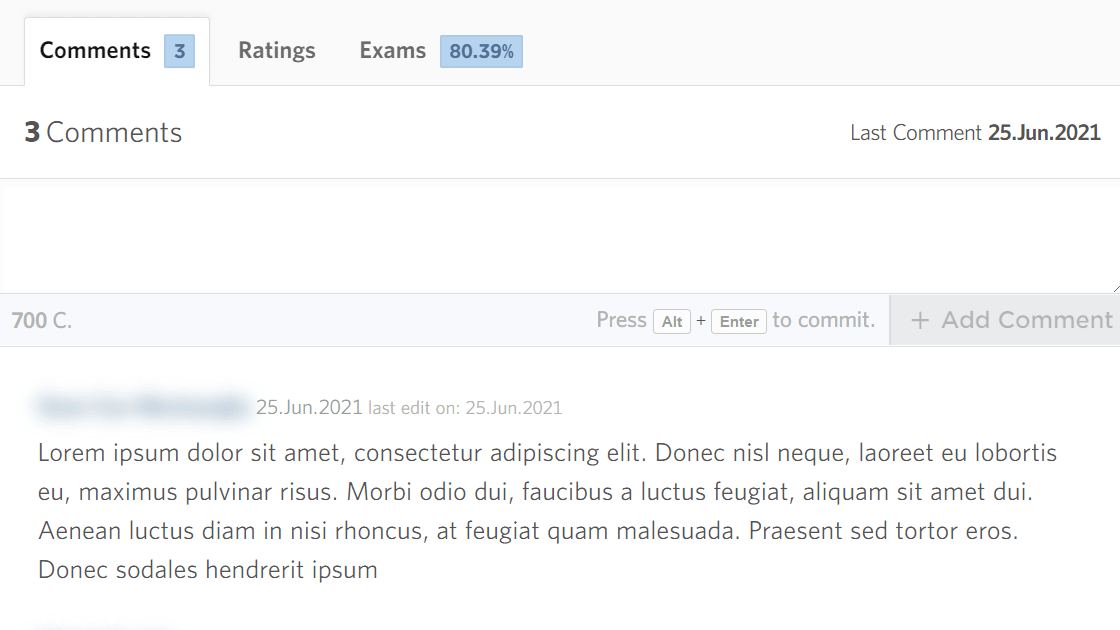

Interact

An easy-to-use commenting system that allows managers and crew converse on a specific task or procedure.

Follow Up

Postponing maintenances allows a more realistic reporting of how a maintenance cycle is completed. Postponing to date or drydock is possible. Maintenances that are postponed to drydock are listed as tasks when that drydock is started.

The planned maintenance setup of a vessel can be viewed in multiple views, these views cover the need to search for tasks in different manners, a tree view, a tree/table combined view, and a table view exist to search, filter, sort, and edit equipment and maintenance.

Work hours can be added to multiple equipment at the same time, or some sub-equipments can be removed from the addition. These additions can then be archived and viewed through multiple places.

Log

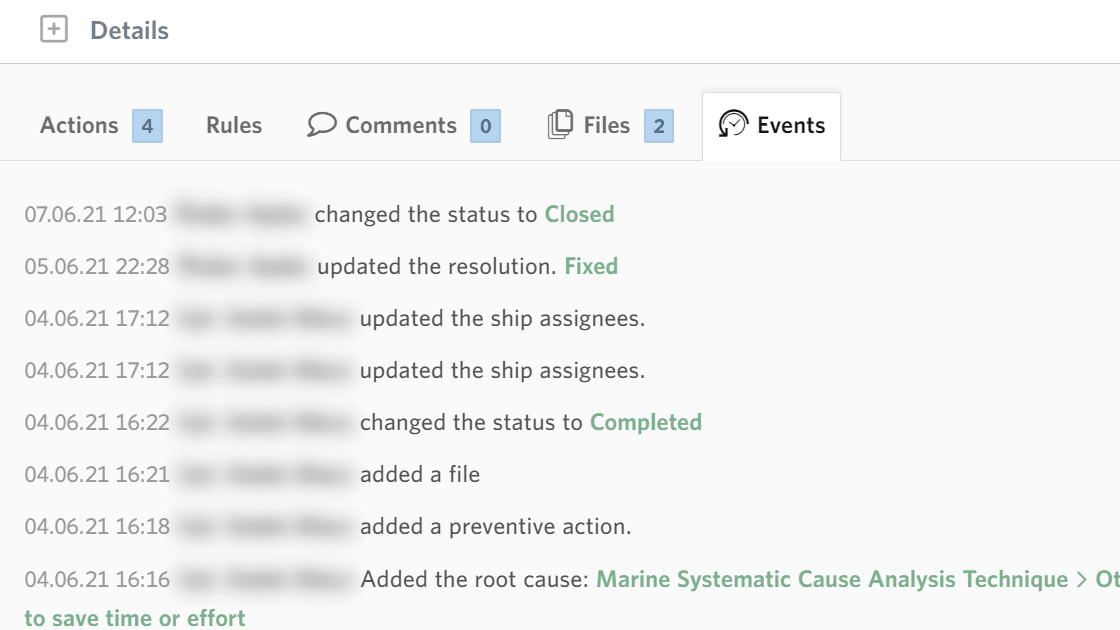

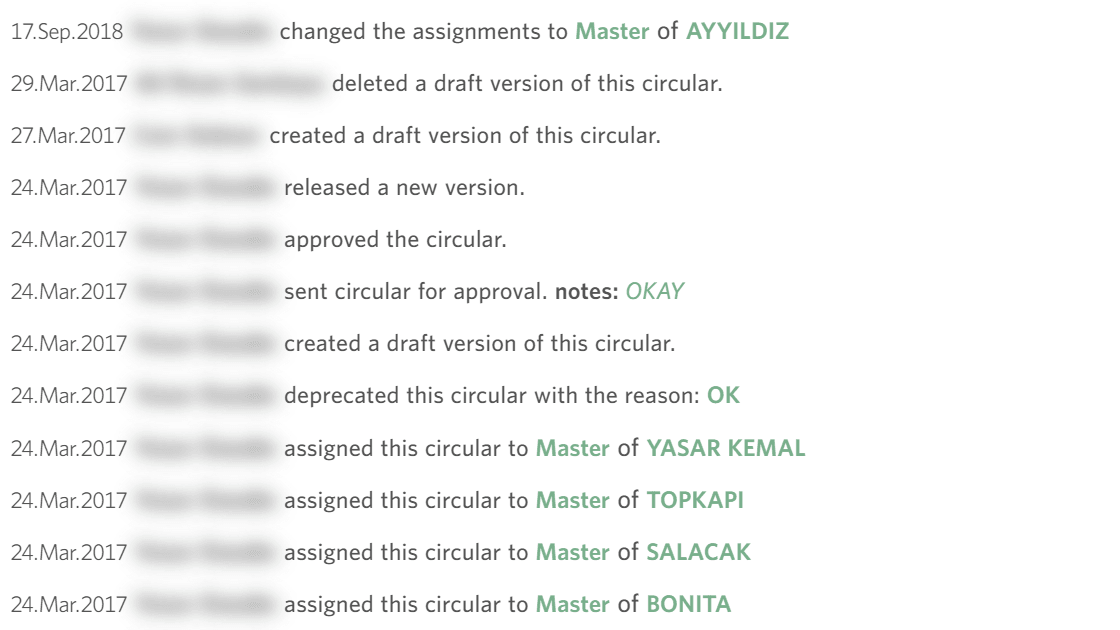

Navatom keeps detailed logs of all actions taken by everyone in your organization.

Manage

As with all features of Navatom, changes to PMS are instantaneously visible by your vessel, and they'll even get a notification about the changes made.

Crew members can report problems with the maintenance they are reporting, such as missing instructions, or wrong periods.

Changes to the PMS are instant, you can update the definition or details of all of the structure, and your vessel will see it instantly.

The tasks can be prioritizing and queuing according to urgency.

Analyze

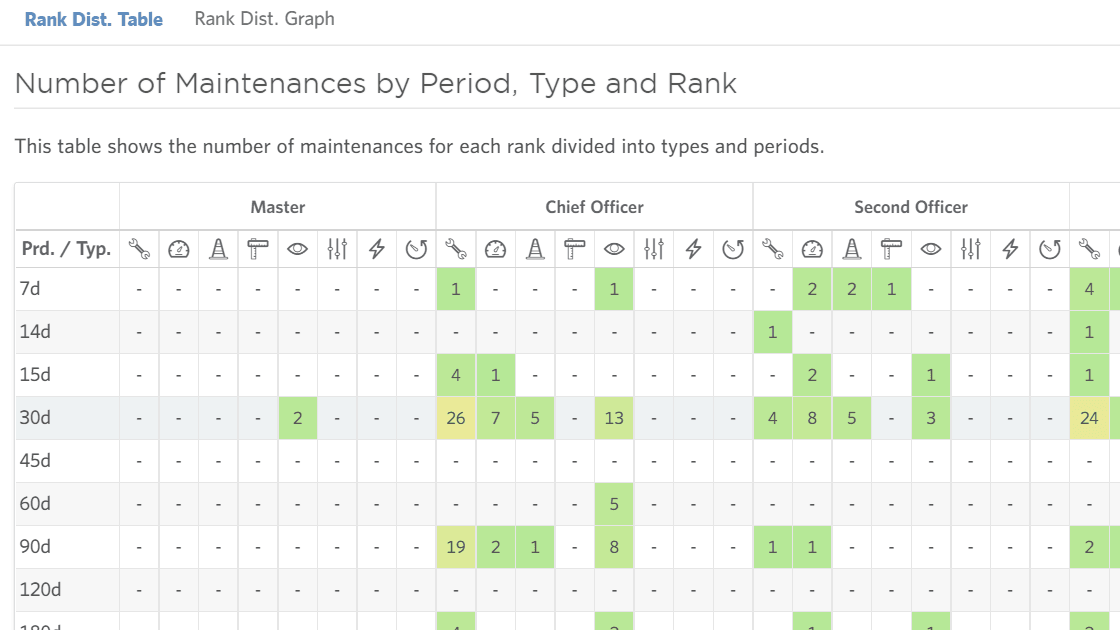

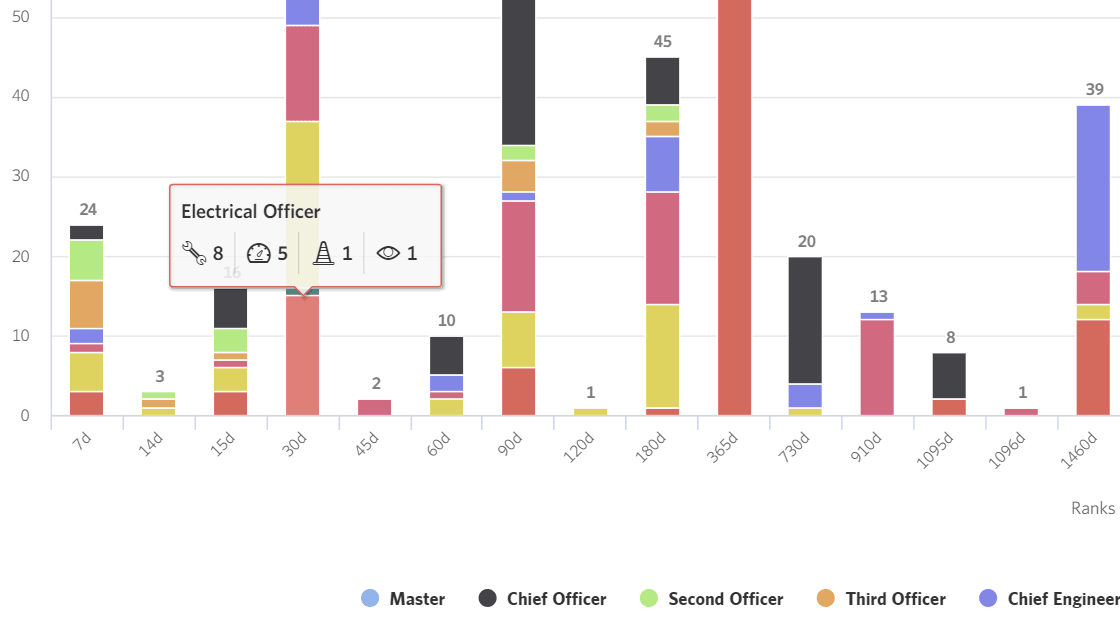

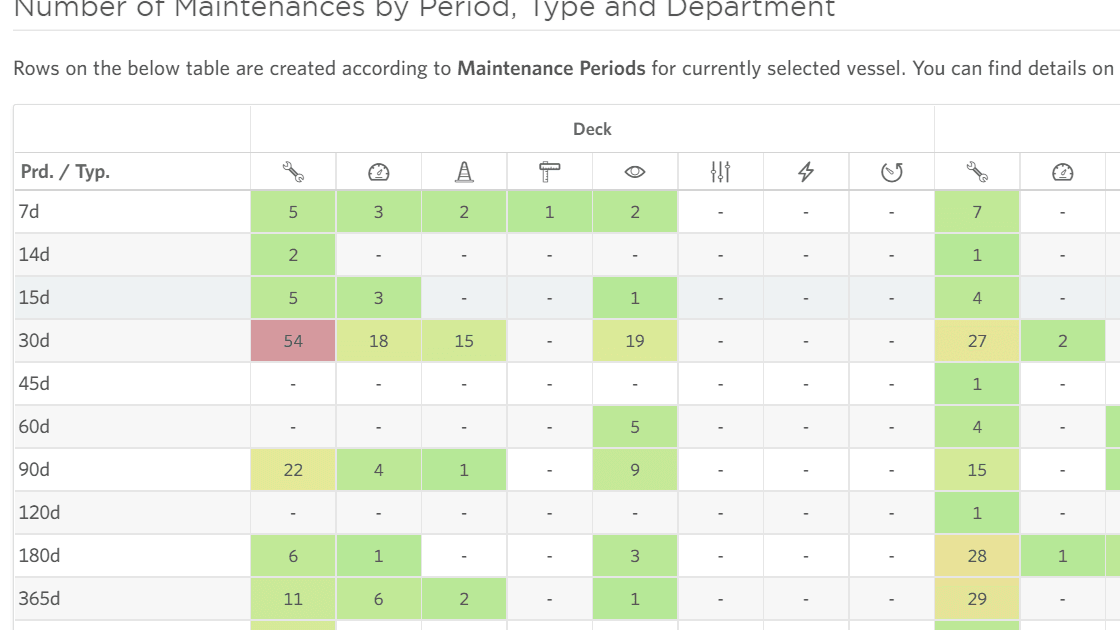

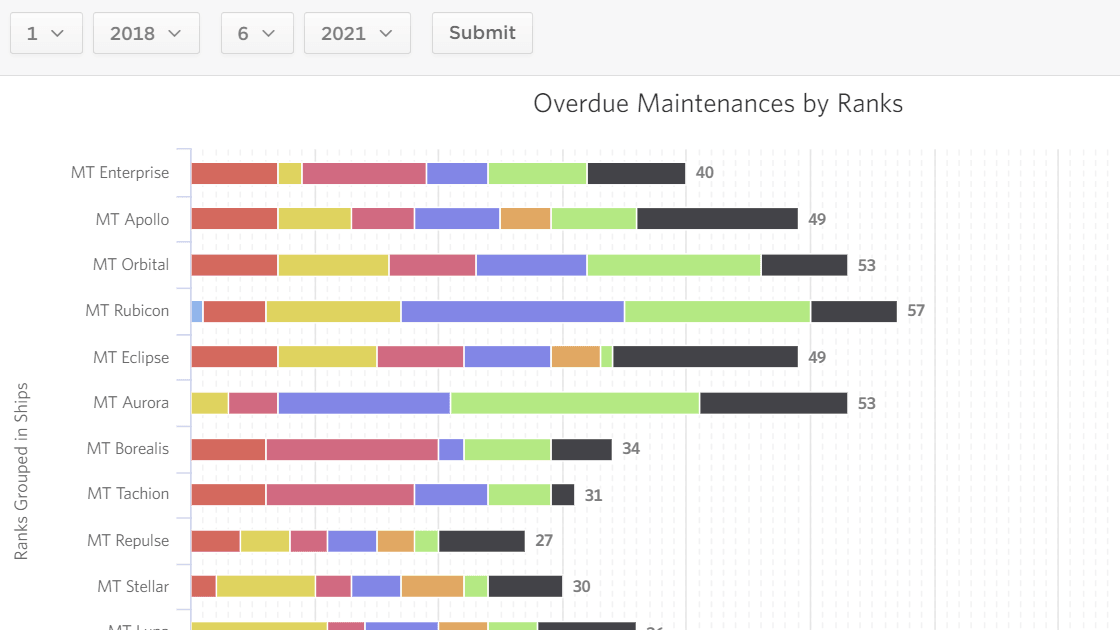

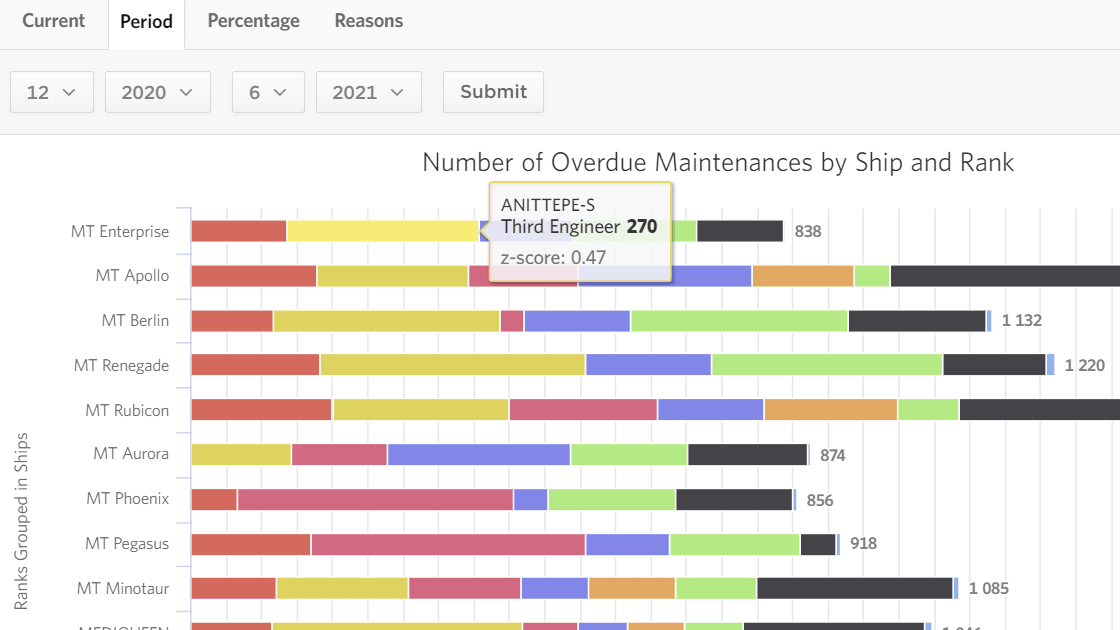

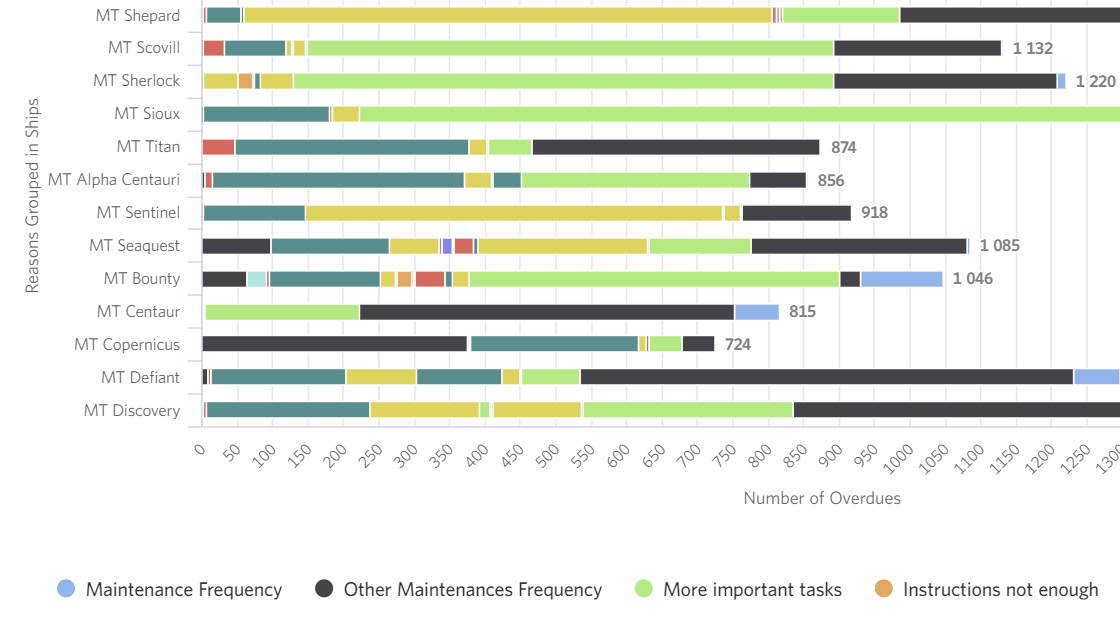

Various tables and graphics visualizing the amount and period of tasks given to crew members.

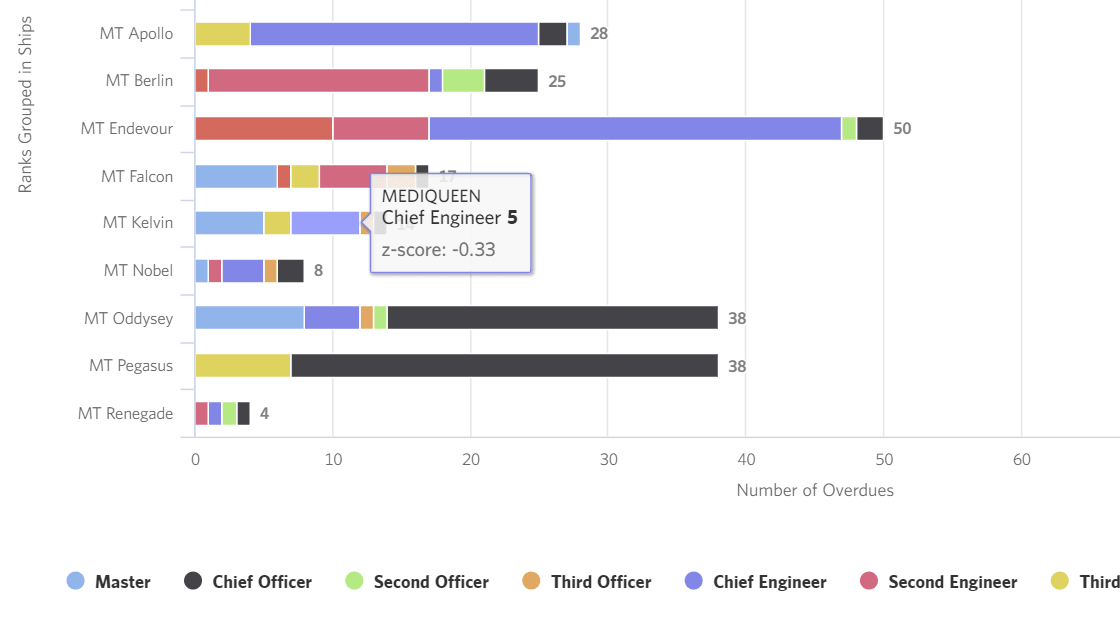

Analyze current and past overdue tasks within your fleet, and see reasons for overdue completion.

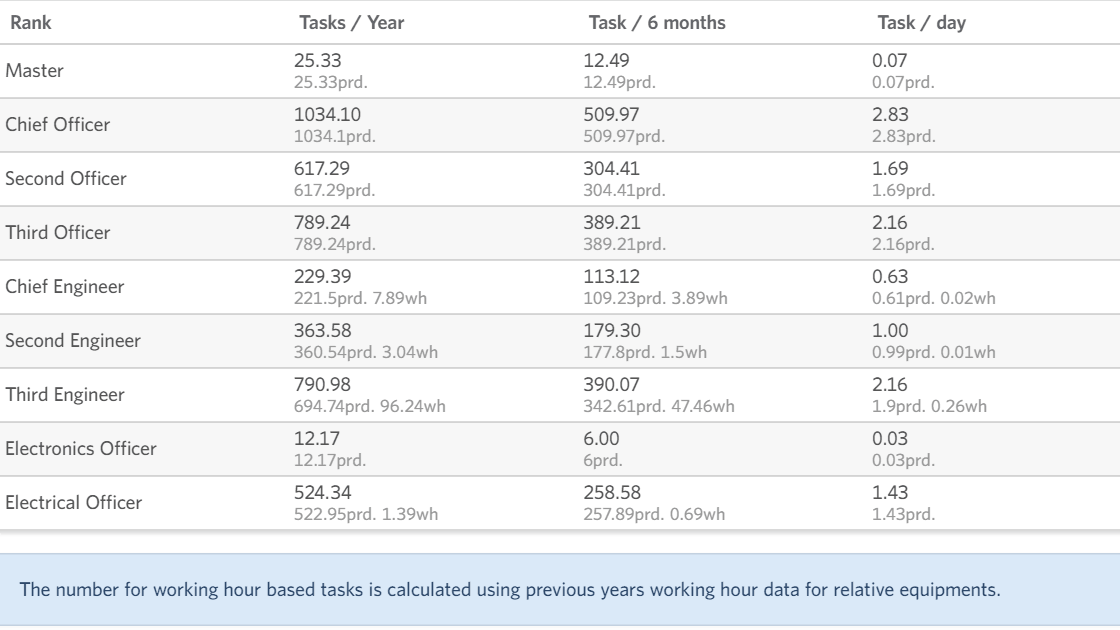

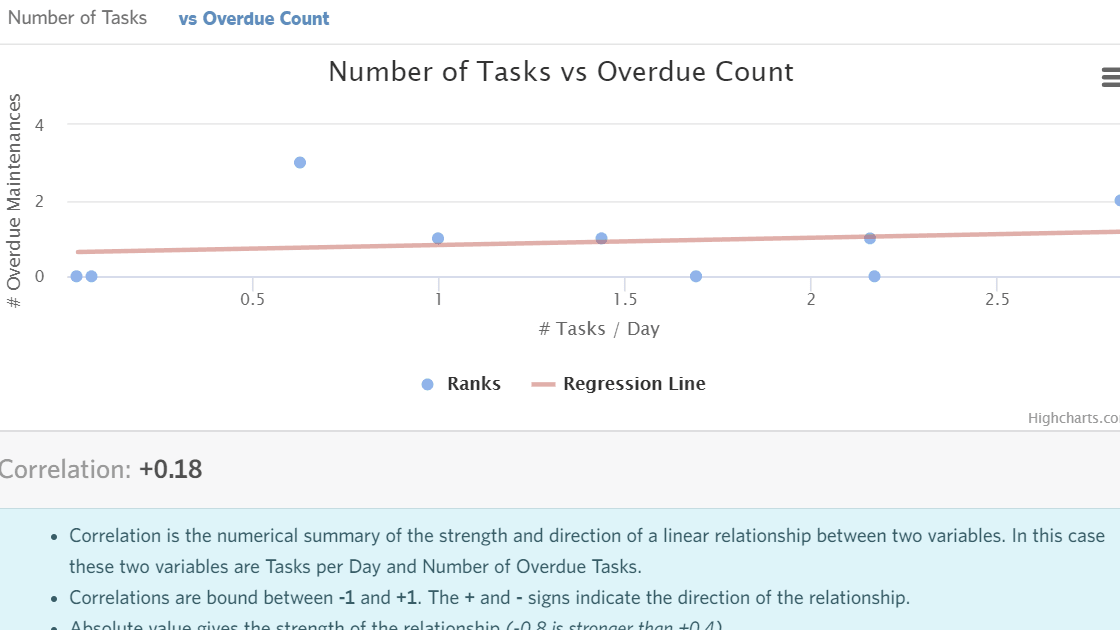

Multiple tables charts and graphs to show how the distribution of PMS tasks between ranks occur. The view also shows the number of tasks per day/6months/year a crew member has to complete on average. A correlation graph shows whether tasks are completed overdue due to over-tasking.